SoFi Stadium

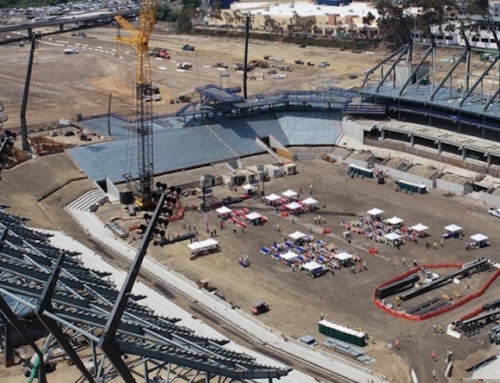

SoFi Stadium is comprised of a seating bowl sunk 100 feet into the ground with giant concrete blade columns positioned in front to support its iconic cable truss roof system. Schuff’s scope of work included the complex roof shell and compression ring, which provides the anchoring for the cable truss system that supports the translucent ETFE material covering the roof.

Project Details

Project Owner:

Contractor:

Turner–AECOM Hunt JV

Structural Engineer:

Architect:

Steel Tonnage:

20,000 tons

Location:

Inglewood, California

Schuff Services: preconstruction, design assist, structural engineering, BIM services, project management, steel detailing, steel fabrication, steel erection

The roof structure is made up of 30 large sections. While 3 sections are significantly larger, every section has slight variations in size due to the geometry of the design. The Schuff Steel team worked hard to design the master plan of hoisting giant pre-assembled sections of the roof into place. Temporary shoring towers were used to jack posts up to the top of concrete columns and a giant crane was assembled to service the first 4,000 tons of steel that arrived on site via heavy haul dual lane trailers and police escort. Each hoisted piece ranged in size up to 250,000 pounds by 100 feet long.

The stadium is home to the Los Angeles Rams and Los Angeles Chargers. Completed, it boasts more than 70,000 seats and sits as the largest building locally with its canopy rising over 53 meters.

Let’s talk about

your next project

SoFi Stadium

Project Details

Project Owner:

Contractor:

Turner–AECOM Hunt JV

EOR:

Architect:

Steel Tonnage:

20,000 tons

Location:

Inglewood, California

Schuff Services: preconstruction, design assist, structural engineering, BIM services, project management, steel detailing, steel fabrication, steel erection

SoFi Stadium is comprised of a seating bowl sunk 100 feet into the ground with giant concrete blade columns positioned in front to support its iconic cable truss roof system. Schuff’s scope of work included the complex roof shell and compression ring, which provides the anchoring for the cable truss system that supports the translucent ETFE material covering the roof.

The roof structure is made up of 30 large sections. While 3 sections are significantly larger, every section has slight variations in size due to the geometry of the design. The Schuff Steel team worked hard to design the master plan of hoisting giant pre-assembled sections of the roof into place. Temporary shoring towers were used to jack posts up to the top of concrete columns and a giant crane was assembled to service the first 4,000 tons of steel that arrived on site via heavy haul dual lane trailers and police escort. Each hoisted piece ranged in size up to 250,000 pounds by 100 feet long.

The stadium is home to the Los Angeles Rams and Los Angeles Chargers. Completed, it boasts more than 70,000 seats and sits as the largest building locally with its canopy rising over 53 meters.