Wilshire Grand

The new Wilshire Grand building will be California’s tallest skyscraper, and the tallest building west of Chicago with an elevation of 1,100 feet. The 73-story high-rise will house 5 stories of underground parking, class A office space, 900 hotel rooms, and retail shops and convention space.

Located in California just 46 miles away from the San Andreas Fault, the Wilshire Grand would need to withstand earthquakes up to a magnitude of 7.4, as well as handle strong winds. The tall slender design of the tower made resistance to seismic activity a challenge for the Schuff Steel team. It meant the structure needed to be dynamic enough to handle environmental forces from both above and below ground.

Project Details

Project Owner:

Contractor:

Structural Engineer:

Architect:

Steel Tonnage:

20,000 tons

Location:

Los Angeles, California

Schuff Services: preconstruction, design assist, structural engineering, BIM services, project management, steel detailing, steel fabrication, steel erection

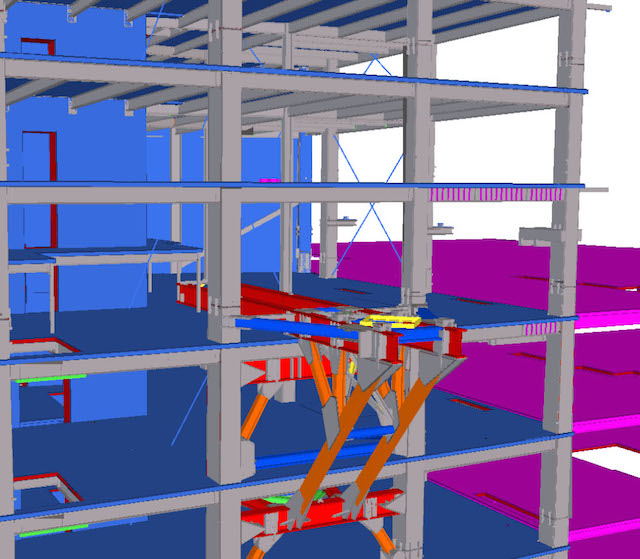

All the potential solutions were put to the test using computer simulations of the structure. The result was a rectangular core comprised of thick walls to anchor structural elements to the outer walls. The Schuff Steel team also helped to integrate 120 single floor BRBs into a 6-story truss system and 50 3-story tall 2,200 kip braces from the core wall to the perimeter belt truss framing for further shock absorption. This included groundbreaking design of the jacking system for pre-compressing (10) BRBs at level 73. The Wilshire Grand project is the first to implement Narrow Gap Electroslag Welding Process in the field that met D1.8 code requirements.

It has been a distinct privilege to work with you, and the Schuff team. Schuff is truly are best in class, and sets the benchmark for excellence.

Thank you again for helping make the Wilshire Grand project so successful.”

Kenneth Aspis, Martin Project Management

Let’s talk about

your next project

Wilshire Grand

Project Details

Project Owner:

Contractor:

Architect:

Steel Tonnage:

20,000 tons

Location:

Los Angeles, California

Schuff Services: preconstruction, design assist, structural engineering, BIM services, project management, steel detailing, steel fabrication, steel erection

The new Wilshire Grand building will be California’s tallest skyscraper, and the tallest building west of Chicago with an elevation of 1,100 feet. The 73-story high-rise will house 5 stories of underground parking, class A office space, 900 hotel rooms, and retail shops and convention space.

Located in California just 46 miles away from the San Andreas Fault, the Wilshire Grand would need to withstand earthquakes up to a magnitude of 7.4, as well as handle strong winds. The tall slender design of the tower made resistance to seismic activity a challenge for the Schuff Steel team. It meant the structure needed to be dynamic enough to handle environmental forces from both above and below ground.

All the potential solutions were put to the test using computer simulations of the structure. The result was a rectangular core comprised of thick walls to anchor structural elements to the outer walls. The Schuff Steel team also helped to integrate 120 single floor BRBs into a 6-story truss system and 50 3-story tall 2,200 kip braces from the core wall to the perimeter belt truss framing for further shock absorption. This included groundbreaking design of the jacking system for pre-compressing (10) BRBs at level 73. The Wilshire Grand project is the first to implement Narrow Gap Electroslag Welding Process in the field that met D1.8 code requirements.

It has been a distinct privilege to work with you, and the Schuff team. Schuff is truly are best in class, and sets the benchmark for excellence.

Thank you again for helping make the Wilshire Grand project so successful.”

Kenneth Aspis, Martin Project Management