UCSF Institute of Regenerative Medicine

Located on UCSF’s Parnassus campus, the 67,000 sq. ft. Institute of Regenerative Medicine supports cutting-edge stem cell research in a seismically active and space-constrained environment. Delivered through a design-build approach, the project team overcame major logistical challenges, including a steep, narrow site with a 90-ft. elevation change, adjacency to occupied buildings, and strict seismic performance requirements.

Project Details

Project Owner:

Contractor:

Structural Engineer:

Architect:

Steel Tonnage:

1,745 tons

Location:

San Francisco, CA

Schuff Services: Project Management, Steel Detailing, Steel Fabrication, Steel Erection, Design Assist

Project Overview

The facility serves as a hub for 24 UCSF scientists and their research teams dedicated to studying the biology of stem cells and translating those discoveries into therapies for currently incurable diseases and debilitating injuries. It houses wet labs, laboratory support areas, offices, and a range of collaboration and meeting spaces. The layout is organized to foster interdisciplinary work while maintaining operational flexibility for evolving scientific programs.

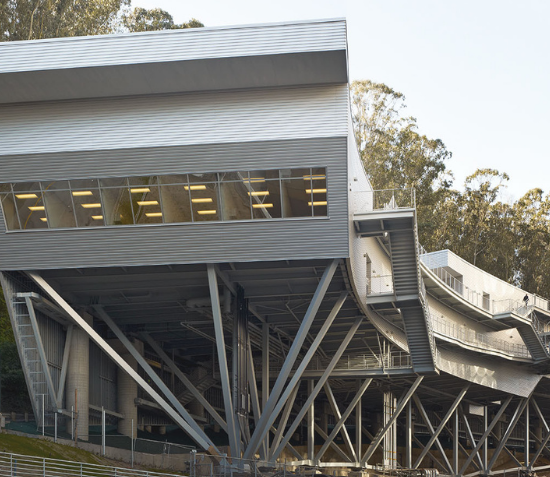

The building features a striking design of four connected pods that resemble inverted pyramids with terraced grass roofs, each stepping up the hillside at 9-ft. intervals. Supported by steel framing and connected to the adjacent Health Science Building by a 130-ft. pedestrian bridge, the facility was designed to meet LEED Gold certification and advanced seismic criteria.

Schuff Steel’s Contributions:

- 1,745 Tons of Structural Steel: Provided detailing, fabrication, and erection for all steel framing, stairs, decking, and pedestrian bridge.

- Seismic Engineering Support: Fabricated and installed 42 Friction Pendulum isolators and eight custom uplift restraints, allowing the structure to move up to 26 inches laterally and 2 inches vertically during seismic events.

- Advanced Fabrication Tolerances: Delivered uplift restraint components with tolerances within 1/1000th of an inch, ensuring reliable seismic performance.

- Design-Assist Collaboration: Worked closely with the design team to address constructability, sequencing, and tolerance issues during ongoing redesigns.

This project demonstrates Schuff Steel’s ability to execute high-precision steel work under challenging site conditions and evolving design requirements.

Let’s talk about

your next project

UCSF Institute of Regenerative Medicine

Project Details

Project Owner:

Contractor:

Structural Engineer:

Architect:

Steel Tonnage:

1,745 tons

Location:

San Francisco, CA

Schuff Services: Project Management, Steel Detailing, Steel Fabrication, Steel Erection, Design Assist

Located on UCSF’s Parnassus campus, the 67,000 sq. ft. Institute of Regenerative Medicine supports cutting-edge stem cell research in a seismically active and space-constrained environment. Delivered through a design-build approach, the project team overcame major logistical challenges, including a steep, narrow site with a 90-ft. elevation change, adjacency to occupied buildings, and strict seismic performance requirements.

The facility serves as a hub for 24 UCSF scientists and their research teams dedicated to studying the biology of stem cells and translating those discoveries into therapies for currently incurable diseases and debilitating injuries. It houses wet labs, laboratory support areas, offices, and a range of collaboration and meeting spaces. The layout is organized to foster interdisciplinary work while maintaining operational flexibility for evolving scientific programs.

The building features a striking design of four connected pods that resemble inverted pyramids with terraced grass roofs, each stepping up the hillside at 9-ft. intervals. Supported by steel framing and connected to the adjacent Health Science Building by a 130-ft. pedestrian bridge, the facility was designed to meet LEED Gold certification and advanced seismic criteria.

Schuff Steel’s Contributions:

- 1,745 Tons of Structural Steel: Provided detailing, fabrication, and erection for all steel framing, stairs, decking, and pedestrian bridge.

- Seismic Engineering Support: Fabricated and installed 42 Friction Pendulum isolators and eight custom uplift restraints, allowing the structure to move up to 26 inches laterally and 2 inches vertically during seismic events.

- Advanced Fabrication Tolerances: Delivered uplift restraint components with tolerances within 1/1000th of an inch, ensuring reliable seismic performance.

- Design-Assist Collaboration: Worked closely with the design team to address constructability, sequencing, and tolerance issues during ongoing redesigns.

This project demonstrates Schuff Steel’s ability to execute high-precision steel work under challenging site conditions and evolving design requirements.