In the Club

One Las Vegas nightclub becomes another thanks to an intricate structural addition and reconfiguration project.

Written by Jorien Baza, P.E., and Patrick M. Hassett, S.E.

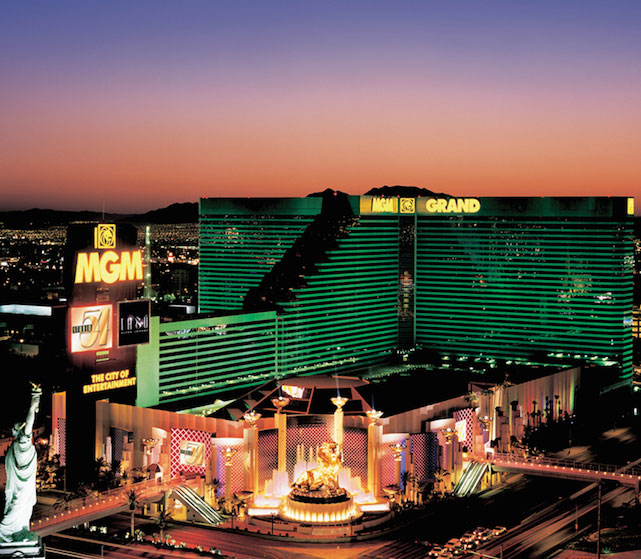

When an old nightclub closes and a new one opens in its place, there are often reminders of the former venue. Not so with the Hakkasan Night Club at the MGM Grand Hotel and Casino in Las Vegas.

The new restaurant and club located in the former Studio 54 space, is a complete transformation. The farming system is part new steel and part overhaul of an existing steel truss dome. The new six-story structure is located on the southwest corner of the existing casino and extends partially into the dome (which is not a true dome shape and would more appropriately be described as an eight-sided pyramid, with eight large raker trusses supporting six stepped octagonal “rings” of trusses). Like the new steel (totalling 1,190 tons), the steel for the original dome was fabricated and erected by Schuff Steel as part of the original MGM Grand construction project in the early 1990s.

The function of the new structure required that some of the steel of the trusses be removed and the trusses retrofitted for their new configurations. The top chords of the trusses being altered were in compression and during construction had to be supported not only vertically for gravity loads but also laterally for buckling in compression.

Another challenge was MGM’s desire for the majority of the existing casino and lounge space located under the dome to remain open and active through the new construction. This required the design, fabrication, and section of a nearly 80-ft-tall, 200-ft-long indoor “temporary” steel wall to keep construction activities completely separate from hotel and casino guests, as well as keep the outdoor elements from affecting the inside of the hotel during the period of demolition of existing portions of walls, facade and roof areas needed to facilitate truss shoring and reinforcing. Further adding complexity was the fact that a portion of the new club and structure was to extend over and tie into the existing Rain Forest Cafe, which MGM also required to remain open for as much of the construction as possible. This required demolition of portions of the cafe and retrofitting of existing columns to support the new higher loads, new truss supports, and dance floor areas being added above.

Demolition and Shoring

Prior to construction of the main steel, the existing framing in the southwest corner of the building had to be demolished and parts of the roof had to be shored before being cut back. Coordination was required between McCarthy Builders, Schuff Steel, Lochsa Engineering and Hassett Engineering to ensure that existing steel was removed in the correct sequence to allow for new steel to be installed and also that any essential shoring was in place before vital steel removal. The first three stages of construction saw the removal of most of the existing steel between the pedestrian walkways at Las Vegas Blvd. and Tropicana Ave. up to the southwest side of the dome. In general, perimeter wall framing was to remain in the final structure.

In order to cut back the roof, a shoring system was developed to support the roof beams on the steel-framed slab-on-metal-deck walkway that extends from Las Vegas Blvd. all the way into the dome. The first set of shoring used temporary HSS4x4 posts on a W8 spreader. The tops of the posts were field welded to the bottom flanges of the roof beams and W16 beams were field welded between the webs of the roof beams to prevent the bottom chords from buckling out of plane. The existing columns and beams were removed and the roof beams were cut back to allow erection of the new elevator tower.

The second set of roof shoring was on the sloped part of the walkway and used HSS4x4 posts to support six roof beams that were to be cut off and attached to new steel. Four of the shoring posts landed directly above a walkway beam and therefore did not require a spreader. However, two of the roof beams needed to be supported out over the edge of the walkway and two cantilever W8 spreader beams were added to be able to place the posts in the desired location.